Product Description

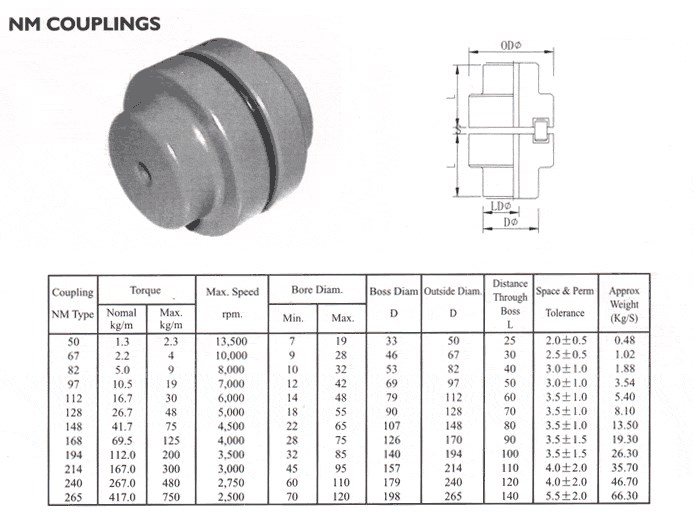

Flexible NM couplings

1. Material: 45#steel and NBR rubber

2. Easy to maintain

3. High precision

4. OEM

Flexible NM couplings advantage:

1. Construction:

1)NM type is precisely produced by a special designed synthetic rubber with 2 similar bodies of cast iron

2)Designed not only for the power transmission but also for protection of flexible rubber

3)Made of rubber and steel cores are inserted in the teeth so as to provide excellent durability and performance of coupling

2. Applications:

Pumps, fans, compressors, vehicles, transporting equipments, constructors, cement mixers, tractors, transmission machines,

Metal working machines, rollers and all other transmissions

3. Features:

1)Economical and practical using

2)Quiet and smooth operation

3)Easy installation and maintenance

4)Available to machines with high torque and intermittent operation

5)Characteristics of the synthetic rubber: Proper elasticity and resistance to damping, oil, acids and alkalies

We can also supply chain coupling, roller chain coupling, rigid couplings, flexible couplings, fcl coupling, flexible rubber fcl coupling, fcl flexible coupling, forged steel fcl coupling, flexible coupling fcl, fcl flexible shaft coupling, jaw coupling, hrc coupling, CHINAMFG coupling, cast steel coupling, aluminum coupling, stainless steel coupling, pin coupling, mh coupling, nm coupling, spacer coupling, taper lock rigid coupling, flange coupling, sleeve coupling, nylon sleeve gear coupling, gear coupling, crc coupling, js coupling

Competitive Advantage:

More than 20 years advanced technology and experience of us will give strong support for coupling you need. We will understand your need of product quickly, and give quick respond and good service. A lot of cases of our products will show you that it worth your trust.

Under the full quality control system, our products go through the precise product line and strict testing process. We have excellent working flow and standard to ensure stability, products reliable enough for using.

Take our scale economy, raw material superiority, and CHINAMFG for clients to account, our price do have a great competitiveness. They are good value and cost effective than your imagine.

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Certification: | ISO |

| Customized: | Non-Customized |

| Model Type: | Xgq-10/120 |

| Main Material: | Stainless Steel |

| Bearing: | Imported NSK |

| Customization: |

Available

| Customized Request |

|---|

How does a flexible coupling handle angular, parallel, and axial misalignment?

A flexible coupling is designed to accommodate various types of misalignment between two rotating shafts: angular misalignment, parallel misalignment, and axial misalignment. The flexibility of the coupling allows it to maintain a connection between the shafts while compensating for these misalignment types. Here’s how a flexible coupling handles each type of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two shafts are not collinear and form an angle with each other. Flexible couplings can handle angular misalignment by incorporating an element that can flex and bend. One common design is the “spider” or “jaw” element, which consists of elastomeric materials. As the shafts are misaligned, the elastomeric element can deform slightly, allowing the coupling to accommodate the angular offset between the shafts while still transmitting torque.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, occurs when the axes of the two shafts are parallel but not perfectly aligned with each other. Flexible couplings can handle parallel misalignment through the same elastomeric element. The flexible nature of the element enables it to shift and adjust to the offset between the shafts, ensuring continuous power transmission while minimizing additional stresses on the machinery.

- Axial Misalignment: Axial misalignment, also called end-play misalignment, occurs when the two shafts move closer together or farther apart along their common axis. Flexible couplings can handle axial misalignment through specific designs that allow limited axial movement. For instance, some couplings use slotted holes or a floating member that permits axial displacement while maintaining the connection between the shafts.

By providing the capability to handle angular, parallel, and axial misalignment, flexible couplings offer several advantages for power transmission systems:

- They help to prevent premature wear and damage to the connected equipment, reducing maintenance and replacement costs.

- They minimize vibration and shock loads, enhancing the overall smoothness and reliability of the machinery.

- They reduce the risk of equipment failure due to misalignment-induced stresses, improving the system’s operational life.

- They allow for easier installation and alignment adjustments, saving time and effort during setup and maintenance.

Overall, flexible couplings play a crucial role in handling misalignment and ensuring efficient power transmission in various industrial applications.

What role does a flexible coupling play in reducing downtime and maintenance costs?

A flexible coupling plays a significant role in reducing downtime and maintenance costs in industrial machinery and rotating equipment. Here are the key ways in which flexible couplings contribute to these benefits:

- Misalignment Compensation: One of the primary functions of a flexible coupling is to accommodate misalignment between two connected shafts. Misalignment can occur due to various factors such as thermal expansion, foundation settling, or manufacturing tolerances. By allowing for misalignment, flexible couplings reduce the transmission of harmful forces and stresses to connected components, minimizing wear and preventing premature failures that could lead to costly downtime and repairs.

- Vibration Damping: Flexible couplings have inherent damping properties due to the elastomeric or flexible elements they incorporate. These elements absorb and dissipate vibration and shock loads that may arise from the operation of rotating machinery. By dampening vibrations, flexible couplings protect the connected equipment from excessive wear and fatigue, extending their service life and reducing the need for frequent maintenance or replacement.

- Shock Load Absorption: In applications where sudden loads or shocks are common, such as in heavy machinery or high-speed equipment, flexible couplings act as shock absorbers. They can absorb and dissipate the impact energy, preventing damage to the machinery and minimizing downtime caused by unexpected failures or breakdowns.

- Easy Installation and Alignment: Flexible couplings are designed for ease of installation and alignment. Unlike rigid couplings that require precise shaft alignment, flexible couplings can tolerate some degree of misalignment during installation. This feature simplifies the setup process, reduces installation time, and lowers the risk of misalignment-related issues, ultimately minimizing downtime during initial installation or replacement of couplings.

- Reduced Maintenance Frequency: The ability of flexible couplings to handle misalignment and dampen vibrations results in reduced wear on bearings, seals, and other connected components. Consequently, the frequency of maintenance intervals can be extended, reducing the need for frequent inspections and component replacements. This directly translates to lower maintenance costs and less downtime for maintenance tasks.

- Equipment Protection: By reducing the transmission of shock loads and vibrations, flexible couplings act as protective barriers for connected equipment. They help prevent catastrophic failures and subsequent damage to expensive machinery, avoiding unplanned shutdowns and costly repairs.

Overall, flexible couplings are critical components that improve the reliability and longevity of rotating equipment. Their ability to handle misalignment, dampen vibrations, and protect against shock loads contributes to reduced downtime, lower maintenance costs, and increased productivity in industrial applications.

Can flexible couplings handle misalignment between shafts?

Yes, flexible couplings are specifically designed to handle misalignment between shafts in rotating machinery and mechanical systems. Misalignment can occur due to various factors, including installation errors, thermal expansion, manufacturing tolerances, or shaft deflection during operation.

Flexible couplings offer the ability to compensate for different types of misalignment, including:

- Angular Misalignment: When the shafts are not collinear and have an angular offset, flexible couplings can accommodate this misalignment by flexing or twisting, allowing the two shafts to remain connected while transmitting torque smoothly.

- Parallel Misalignment: Parallel misalignment occurs when the two shafts are not perfectly aligned along their axes. Flexible couplings can adjust to this misalignment, ensuring that the shafts remain connected and capable of transmitting power efficiently.

- Axial Misalignment: Axial misalignment, also known as end float or axial displacement, refers to the relative axial movement of the two shafts. Some flexible coupling designs can accommodate axial misalignment, allowing for slight axial movements without disengaging the coupling.

The ability of flexible couplings to handle misalignment is essential in preventing premature wear and failure of the connected equipment. By compensating for misalignment, flexible couplings reduce the stress on the shafts, bearings, and seals, extending the service life of these components and improving overall system reliability.

It is crucial to select the appropriate type of flexible coupling based on the specific misalignment requirements of the application. Different coupling designs offer varying degrees of misalignment compensation, and the choice depends on factors such as the magnitude and type of misalignment, the torque requirements, and the operating environment.

In summary, flexible couplings play a vital role in handling misalignment between shafts, ensuring efficient power transmission and protecting mechanical systems from the adverse effects of misalignment. Their ability to accommodate misalignment makes them indispensable components in various industrial, automotive, aerospace, and marine applications.

editor by CX 2024-05-13