Product Description

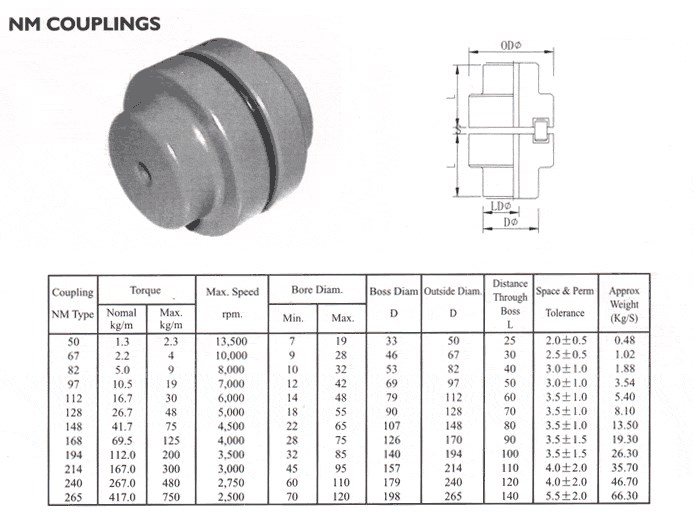

| Product Name | nm coupling |

| Material | cast iron |

| Type | nm 50-214 |

| Structure | 2 shaft ( 1 / 1a / 1b )+spider |

| Bore size | 7-952mm |

| Weight | About 0.48-35.7 kg / pcs |

| packing | plastic bag +paper box +wooden box +wooden pallet |

Flexible Coupling/Couplings

1. One Piece metallic spring coupling

2. Zero backlash

3. Absorption of parallel, angular misalignment and shaft end-play by spring action

4. Identical clockwise and anticlockwise rotational characteristics

5. Setscrew type or Clamp Type

6. Material: Aluminum Alloy or Stainless steel or other materials per customers’ request.

7. Anti-corrsion,widely used in medical science ,chemistry

8. High flexibilty

9. For servomotor stepmotor

What applications are coupling used for?

Couplings are used in servo drive technology, machine tools, packaging machinery, automation systems, printing presses, industrial robots, control and positioning technology, and general mechanical engineering.

MAIN PRODUCTS:

1) Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2) Forging, Casting, Stampling Part;

3) V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4) Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5) Shaft Coupling:including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling, Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6) Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7) Timing Belt: including Rubber and PU timing belts for industrial;

8) Other customized Machining Parts according to drawings (OEM).

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | 1.3-300 |

| Bore Diameter: | 7-952 |

| Speed: | 3000-13500 |

| Structure: | Flexible |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a flexible coupling handle angular, parallel, and axial misalignment?

A flexible coupling is designed to accommodate various types of misalignment between two rotating shafts: angular misalignment, parallel misalignment, and axial misalignment. The flexibility of the coupling allows it to maintain a connection between the shafts while compensating for these misalignment types. Here’s how a flexible coupling handles each type of misalignment:

- Angular Misalignment: Angular misalignment occurs when the axes of the two shafts are not collinear and form an angle with each other. Flexible couplings can handle angular misalignment by incorporating an element that can flex and bend. One common design is the “spider” or “jaw” element, which consists of elastomeric materials. As the shafts are misaligned, the elastomeric element can deform slightly, allowing the coupling to accommodate the angular offset between the shafts while still transmitting torque.

- Parallel Misalignment: Parallel misalignment, also known as offset misalignment, occurs when the axes of the two shafts are parallel but not perfectly aligned with each other. Flexible couplings can handle parallel misalignment through the same elastomeric element. The flexible nature of the element enables it to shift and adjust to the offset between the shafts, ensuring continuous power transmission while minimizing additional stresses on the machinery.

- Axial Misalignment: Axial misalignment, also called end-play misalignment, occurs when the two shafts move closer together or farther apart along their common axis. Flexible couplings can handle axial misalignment through specific designs that allow limited axial movement. For instance, some couplings use slotted holes or a floating member that permits axial displacement while maintaining the connection between the shafts.

By providing the capability to handle angular, parallel, and axial misalignment, flexible couplings offer several advantages for power transmission systems:

- They help to prevent premature wear and damage to the connected equipment, reducing maintenance and replacement costs.

- They minimize vibration and shock loads, enhancing the overall smoothness and reliability of the machinery.

- They reduce the risk of equipment failure due to misalignment-induced stresses, improving the system’s operational life.

- They allow for easier installation and alignment adjustments, saving time and effort during setup and maintenance.

Overall, flexible couplings play a crucial role in handling misalignment and ensuring efficient power transmission in various industrial applications.

Can flexible couplings be used in applications with varying operating temperatures?

Yes, flexible couplings can be used in applications with varying operating temperatures. The suitability of a flexible coupling for a specific temperature range depends on its design and the materials used in its construction. Different types of flexible couplings are available to handle a wide range of temperature conditions, making them versatile for use in various industries and environments.

High-Temperature Applications:

For applications with high operating temperatures, such as those found in certain industrial processes, exhaust systems, or high-temperature machinery, flexible couplings made from materials with excellent heat resistance are used. These materials may include stainless steel alloys, heat-treated steels, or specialized high-temperature elastomers. High-temperature flexible couplings are designed to maintain their mechanical properties, including flexibility and torque transmission capabilities, even at elevated temperatures.

Low-Temperature Applications:

Conversely, for applications in extremely cold environments or cryogenic processes, flexible couplings constructed from materials with low-temperature resistance are employed. These couplings are designed to remain flexible and functional at very low temperatures without becoming brittle or losing their ability to handle misalignment. Some low-temperature couplings may use special polymers or elastomers with excellent cold-temperature performance.

Temperature Range Considerations:

When selecting a flexible coupling for applications with varying operating temperatures, it is essential to consider the specific temperature range in which the coupling will operate. Some flexible couplings have a wider temperature range, allowing them to function effectively in both high and low-temperature environments. However, in extreme temperature conditions, specialized couplings may be necessary to ensure reliable performance and prevent premature failure.

Manufacturer Guidelines:

Manufacturers of flexible couplings provide guidelines and specifications regarding the temperature range of their products. It is crucial to consult the manufacturer’s documentation to ensure that the chosen coupling is suitable for the intended operating temperature of the application. Using a coupling beyond its recommended temperature range can lead to performance issues, reduced efficiency, or even failure.

Applications:

Flexible couplings with varying temperature resistance find use in numerous industries, including aerospace, automotive, manufacturing, power generation, and more. Whether in high-temperature exhaust systems, low-temperature cryogenic processes, or regular industrial applications with temperature fluctuations, flexible couplings play a vital role in providing reliable power transmission and misalignment compensation.

In summary, flexible couplings can be effectively used in applications with varying operating temperatures, provided that the coupling’s design and material properties align with the specific temperature requirements of the application.

How do you select the appropriate flexible coupling for a specific application?

Choosing the right flexible coupling for a specific application requires careful consideration of various factors to ensure optimal performance, reliability, and longevity. Here are the key steps to select the appropriate flexible coupling:

- Application Requirements: Understand the specific requirements of the application, including torque and speed specifications, misalignment conditions, operating environment (e.g., temperature, humidity, and presence of corrosive substances), and space limitations.

- Torque Capacity: Determine the maximum torque that the coupling needs to transmit. Choose a flexible coupling with a torque rating that exceeds the application’s requirements to ensure a safety margin and prevent premature failure.

- Misalignment Compensation: Consider the type and magnitude of misalignment that the coupling needs to accommodate. Different coupling designs offer varying degrees of misalignment compensation. Select a coupling that can handle the expected misalignment in the system.

- Vibration Damping: If the application involves significant vibrations, choose a flexible coupling with good damping properties to reduce vibration transmission to connected equipment and improve system stability.

- Environmental Factors: Take into account the environmental conditions in which the coupling will operate. For harsh environments, consider couplings made from corrosion-resistant materials.

- Torsional Stiffness: Depending on the application’s requirements, decide on the desired torsional stiffness of the coupling. Some applications may require high torsional stiffness for precise motion control, while others may benefit from a more flexible coupling for shock absorption.

- Cost and Life-Cycle Considerations: Evaluate the overall cost-effectiveness of the coupling over its expected life cycle. Consider factors such as initial cost, maintenance requirements, and potential downtime costs associated with coupling replacement.

- Manufacturer Recommendations: Consult coupling manufacturers and their technical specifications to ensure the selected coupling is suitable for the intended application.

- Installation and Maintenance: Ensure that the selected flexible coupling is compatible with the equipment and shaft sizes. Follow the manufacturer’s installation guidelines and recommended maintenance practices to maximize the coupling’s performance and longevity.

By following these steps and carefully evaluating the application’s requirements, you can select the most appropriate flexible coupling for your specific needs. The right coupling choice will lead to improved system performance, reduced wear on equipment, and enhanced overall reliability in various mechanical systems and rotating machinery.

editor by CX 2023-08-04